|

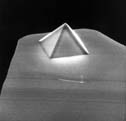

It operates by measuring attractive or repulsive forces between a tip and the sample. In repulsive "contact" mode mode, the instrument lightly touches a tip at the end of a leaf spring or "cantilever" to the sample. As a raster-scan drags the tip over the sample, some sort of detection apparatus measures the vertical deflection of the cantilever, which indicates the local sample height. Hence, AFM resembles the record player as well as the stylus profilometer and unlike electron microscopes, can generally image samples in air and under liquids. |

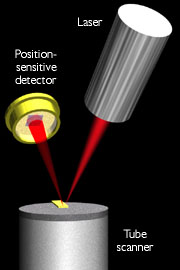

| The optical lever operates by reflecting a laser beam off the cantilever. Angular deflection of the cantilever causes double the angular deflection of the laser beam. The reflected laser beam strikes a position-sensitive photodetector consisting of two side-by-side photodiodes. The difference between the two photodiode signals indicates the position of the laser spot on the detector and thus the angular deflection of the cantilever. Because the cantilever-to-detector distance generally measures thousands of times the length of the cantilever, the optical lever greatly magnifies (~2000-fold) motions of the tip. |

|

| Schematic illustration of the meaning of spring constant as applied to AFM cantilevers. Visualizing the cantilever as a coil spring, its spring constant k directly affects the downward force exerted on the sample. |

|

|

|

|

|

|

|

| The feedback loop consists of the tube scanner, sample, cantilever and optical lever, and a feedback circuit. It is the compensation network (a computer program) that monitors the cantilever deflection and attempts to keep it constant by varying the voltage applied to the scanner and hence adjusts the height of the sample. Hence an AFM can measure sample topography in two ways: by recording the feedback output ("Z") or the cantilever deflection ("C"). The sum of these two signals always yields the actual topography, but given a well-adjusted feedback loop, the error signal should be negligible. |